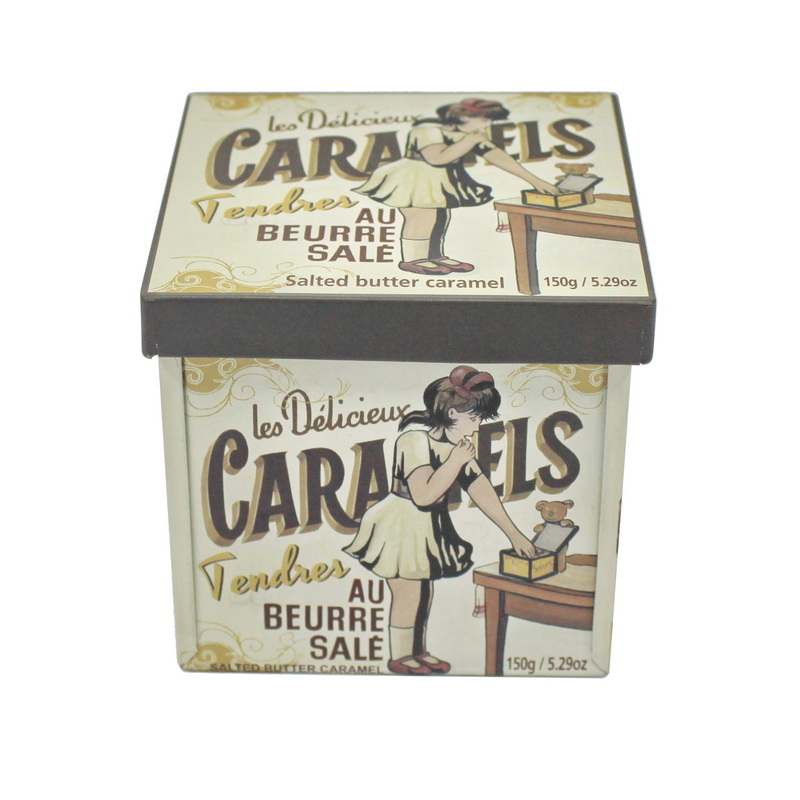

OEM order round cookie tin box food container muffins tins biscuit tins

|

Product name : |

OEM order round cookie tin box food container |

|

Material : |

0.23 mm tinplate |

|

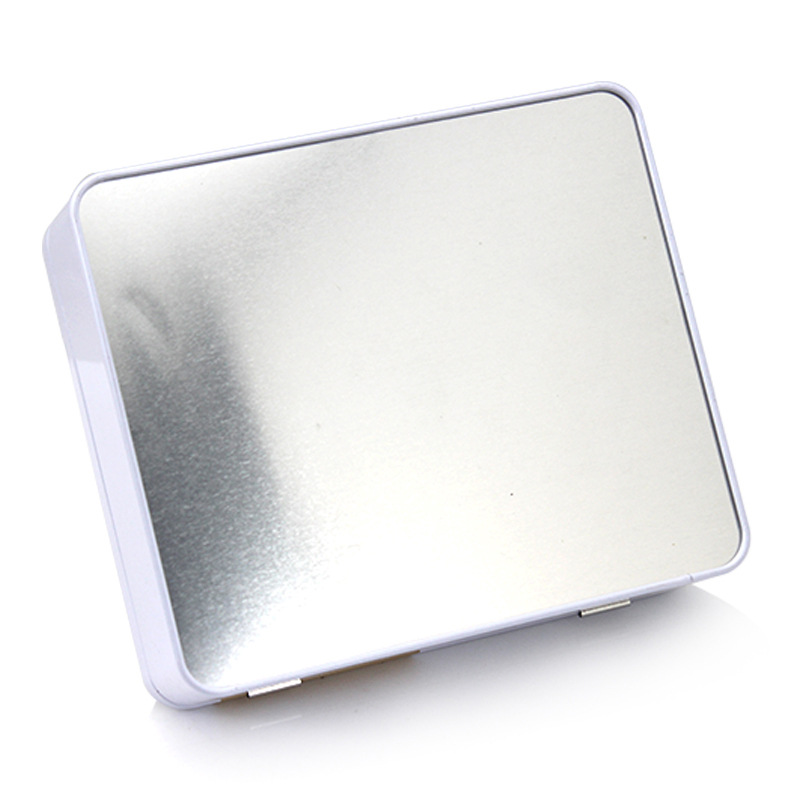

Design : |

Customized design, OEM, Customer Logo |

|

Dimensions : |

Dia168 H60 mm |

|

Color : |

Silver /CMYK / PMS |

|

Surface Finishing : |

gloss or matt varnishing |

|

Shape : |

Round shape |

|

Usage : |

Gift tin to pack donuts or cookies or chocolates |

|

Packing details : |

each in polybag, inner box, carton |

|

Payment terms : |

L/C, D/P, T/T |

|

Delivery time : |

30 days after confirming the sample and receiving the deposit |

|

Loading port : |

Yantian, Hong Kong |

|

Remarks : |

Different materials, colors, styles, shapes, artwork and printing are acceptable according to customers' demands |

Tags: Food Packaging Tins

What are the environmental implications and sustainability considerations associated with the use of food packaging tins compared to other packaging materials like plastic or glass?

The environmental impact and sustainability considerations of the use of food packaging tins include:

Environmental impact:

Recyclability: Food packaging tins mainly made of steel or aluminum have high recyclability. Recycling these materials reduces the demand for raw resources and reduces the environmental impact associated with mining and processing of raw materials.

Energy intensity: The production of metal cans, especially aluminum, may be energy intensive. However, the energy consumption for recycling is significantly lower than that for producing new materials, making recycling a favorable option.

Durability: Canned food is durable and can resist external factors such as light, moisture, and air, helping to extend the shelf life of food and reduce food waste.

Sustainability considerations:

Recycling rate: The high recycling rate of metal packaging contributes to sustainable development. Efforts should be encouraged to increase the collection and recycling of metal cans to reduce the demand for new products.

Resource protection: The use of recycled metals in tin production can protect natural resources and reduce the impact of mining and mining on the environment.

Reduce waste: Metal packaging can maintain the quality and freshness of food, prevent spoilage and pollution, and thus help reduce food waste.

Transportation efficiency: Metal cans are lightweight, which helps improve transportation efficiency and reduce carbon emissions during transportation.

Comparison with plastic and glass:

Plastic: Although plastic packaging is lightweight and widely used, it has raised concerns about plastic pollution and its impact on ecosystems.

Glass: Glass packaging is recyclable and inert, but it is heavier than metal cans, resulting in higher transportation emissions. Glass may also be more fragile and prone to breakage.

Multi material packaging: Some packaging solutions combine materials such as plastic and metal to optimize product protection and sustainability. These hybrid designs aim to leverage the advantages of each material while minimizing its weaknesses.

What are the safety and regulatory standards that food packaging tins must meet to ensure the protection of food products?

Food packaging tins, like other food contact materials, must meet safety and regulatory standards to ensure the protection of food products and the health of consumers. The specific regulations may vary by country or region, but there are some common international guidelines and standards.

Food Contact Materials Regulations: Food packaging tins must comply with the regulations specific to food contact materials in the relevant jurisdiction. In the United States, this includes the Food Contact Substance (FCS) notification process, while in the European Union, it involves compliance with the European Food Contact Materials Regulation (EC) No 1935/2004.

Material Safety: The materials used in food packaging tins, such as steel or aluminum, must meet safety standards. They should not release harmful substances or contaminants into the food. These materials should be tested for their suitability for contact with food.

Migration Limits: Regulatory bodies set specific migration limits for substances that may migrate from packaging materials into food. This includes limits for heavy metals, such as lead and cadmium, which are restricted due to their potential health risks.

Ink and Coatings: If food packaging tins are printed or coated, the inks and coatings used must be food-grade and non-toxic. They should not contain harmful chemicals that can transfer to the food.

Microbiological Safety: Food packaging tins should be designed and manufactured to prevent contamination from microorganisms. Proper cleaning and sanitization processes in the manufacturing facilities are crucial.

Labeling and Information: Packaging must provide clear and accurate information about the contents, expiration dates, storage conditions, and any special handling instructions to ensure the safe use of the food product.

Foreign Substances Control: Measures should be in place to prevent foreign substances from entering the packaging during the manufacturing and filling processes. This includes the use of metal detectors and other quality control checks.

Good Manufacturing Practices (GMP): Food packaging manufacturers must adhere to GMP guidelines, which cover the design, construction, maintenance, and operation of facilities. GMP ensures hygienic and safe production processes.

Hazard Analysis and Critical Control Points (HACCP): The HACCP system is applied to identify and control potential hazards in food production, including packaging processes, to prevent food safety risks.

ISO Standards: Some manufacturers adhere to ISO standards, such as ISO 22000 for food safety management systems, to demonstrate their commitment to food safety and quality.

Regulatory Compliance Documentation: Manufacturers and suppliers of food packaging tins often need to provide documentation demonstrating compliance with safety regulations. This may include certificates of compliance and test reports.

Consumer Safety: Packaging should be designed to minimize the risk of injury during use and disposal, such as sharp edges or easy-to-open features for child-resistant packaging.